Bambu Lab’s 3D printers are renowned for their automated calibration features that ensure optimal print quality even at high speeds. Instead of tedious manual tuning, these printers use built-in sensors (force sensors, LiDAR lasers, eddy current sensors, etc.) to auto-adjust critical settings like bed levelling, nozzle height, flow rates, and more.

In this Bambu Lab Calibration Guide, we focus on calibration techniques across the Bambu P1 series, X1 series, A1 (including A1 Mini), and the dual-nozzle H2D – highlighting how each calibration works and tips to get the most out of them. Whether you’re a beginner who relies on Bambu’s automatic wizards or an advanced user looking to fine-tune every parameter, this guide will help you achieve perfect first layers, smooth extrusion, and minimal artifacts in your prints.

We’ll cover all modes of calibration (bed tramming, auto bed levelling, flow dynamics calibration a.k.a. pressure advance, flow rate tuning, vibration compensation, motor noise cancellation, and dual-nozzle alignment) with both technical insights and some “Explain Like I’m 5” analogies for the tricky concepts.

Table of Contents

Let’s dive in and unlock the full potential of Bambu Lab’s calibration system – the key to transforming a good printer into a great one for consistently high-quality results.

Calibration matters

Even though Bambu printers are well-tuned out of the box, small variations in each machine and each filament mean calibration is essential to reach perfection. As one community expert puts it, “No matter how carefully built, every machine is slightly different – Bambu printers are good out of the box but make yours great by calibrating”.

Likewise, every filament brand and even color can behave differently, so dialing in those settings can dramatically improve your print quality. In the following sections, we’ll explain each calibration and how to perform it on different Bambu models, with tips gleaned from the official Bambu Lab Wiki and user feedback from the community.

(Before starting:) Update your firmware/software. Some calibration features (e.g. A1 Mini’s auto flow calibration) require the printer firmware and Bambu Studio to be up-to-date. Also, ensure your printer is mechanically sound – bolts tight, nozzles clean, bed clean – so that sensors can do their job accurately. Now, onto the calibrations!

Bambu’s Auto-Calibration System Overview

Bambu Lab printers are designed to largely calibrate themselves.

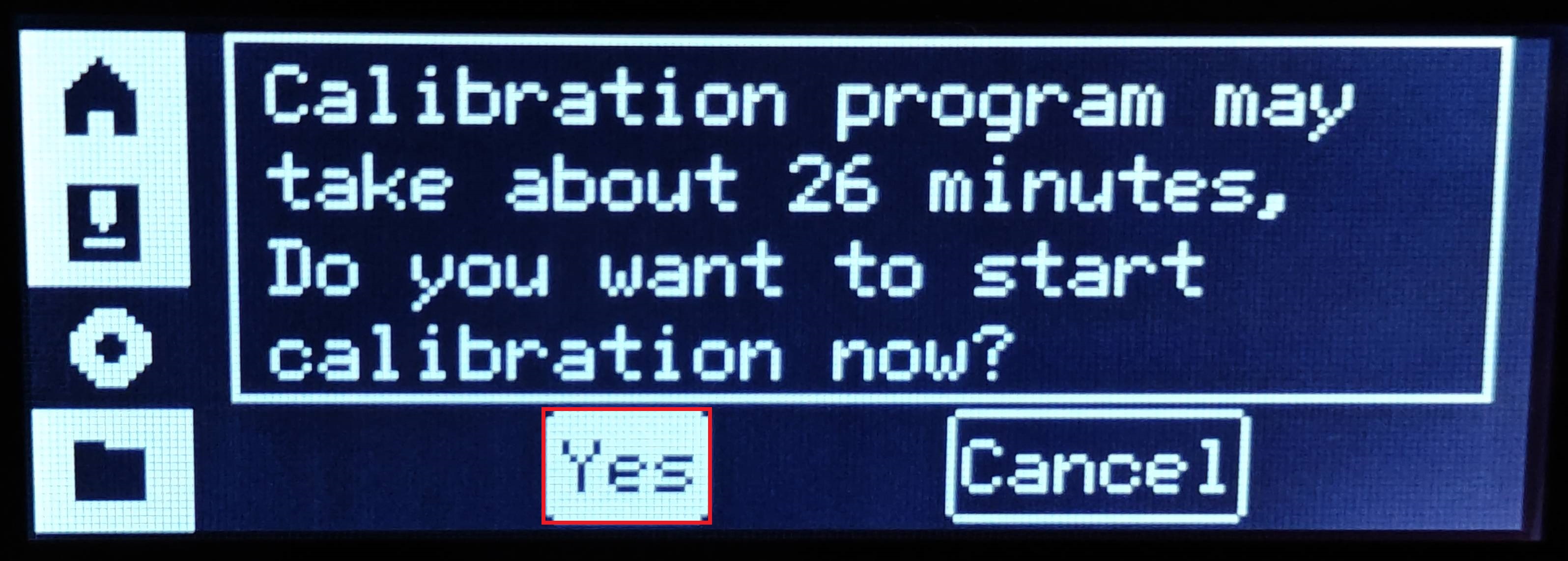

On the X1 series, tapping “Calibrate” on the screen presents four calibration routines ready to run.

On the P1 series and A1 series, the interface is slightly different but still offers easy access to calibration options. These auto-calibrations adjust the printer’s bed levelling, nozzle height (Z-offset), vibration compensation, and motor noise cancellation using sensors. For example, the X1 Carbon (X1C) famously uses a Dual Auto Bed Levelling system: it has force sensors in the bed to detect when the nozzle touches the plate, plus an onboard micro LiDAR scanner – the two methods cross-check each other for extra reliability.

This means the X1 can achieve very precise bed levelling and first-layer calibration without user intervention. The P1 series also uses force sensors for bed levelling (it lacks LiDAR) but still automates the process of creating a bed height mesh. The A1 series (including A1 Mini) likewise has auto bed levelling; it’s hardware uses similar principles (force sensing) even though it’s a smaller format.

Auto Bed Levelling (ABL)

Auto Bed Levelling (ABL) is run at the start of prints (unless disabled) and you can also trigger it manually via the Calibration menu. It ensures the printer knows the shape of your bed (level or any slight tilts) so it can adjust Z height during printing. However, note that ABL can only compensate within limits – if your bed is severely out of tram, you should manually level it first (more on that next). The key point is auto bed levelling works best when the bed is physically flat to begin with. Bambu Lab ships the beds pre-trammed, but shipping vibrations can knock things out. So if you have first-layer issues, don’t hesitate to perform a manual bed tramming as a first step.

Nozzle Height & Vibration Compensation Calibration

Beyond leveling, Bambu’s “auto calibration” covers other tuning: Nozzle height (Z offset) calibration ensures the nozzle’s distance from the bed is correct (a worn or dirty nozzle can throw this off, so the machine occasionally checks and might warn you if, say, “nozzle height seems too low/high”). Vibration compensation calibration (also called resonance compensation or input shaping) measures the printer’s resonant frequencies so it can adjust movement to cancel out ringing. And motor noise cancellation calibration measures the steppers’ vibration characteristics to actively reduce noise during printing. We’ll delve into each of these later.

In short, Bambu Lab printers are equipped with a suite of sensors and routines that largely calibrate the machine automatically – a huge convenience compared to manual calibration on other printers. Now let’s go step by step through each type of calibration, with an eye on how to use it and how the different models (P1, X1, A1, H2D) implement it.

Bed Leveling (Bed Tramming) and Nozzle Height Calibration

Achieving a perfect first layer starts with a level print bed (also known as bed tramming). “Level” in this context means the bed’s surface is the same distance from the nozzle at all points – it’s nothing to do with true horizontal alignment to gravity. Bambu printers use a combination of manual tramming (if needed) and automatic mesh levelling. The general recommendation is: If your first layer isn’t consistent, first verify the bed’s mechanical levelling, then rely on the auto levelling to fine-tune.

Manual Bed Tramming

The X1 and P1 series printers have three bed levelling thumb screws underneath the bed. These are factory-set, but if you see that one side of your first layer is too squished or too high relative to the other, it might mean the bed isn’t planar to the gantry. Bambu provides a guided tramming procedure using a special G-code file. Essentially, the printer homes, then moves the nozzle to each corner and pauses while you adjust the corresponding screw until the nozzle just “kisses” the plate (often using a piece of paper or feeler gauge to judge the gap).

The process repeats multiple times for fine adjustments. After manual levelling, you should tighten any loose bed mounting screws again to lock it in. Bambu’s wiki states this should only be done if needed (e.g., after shipping or if specifically instructed), but many users have found doing a manual tram when the printer is new is worth the 5-10 minutes. “New, out of the box is not necessarily aligned… take your time and do it right, everything else depends on this being right,” as one community guide emphasizes. In other words, get the bed mechanically flat first.

Auto Bed Levelling (ABL)

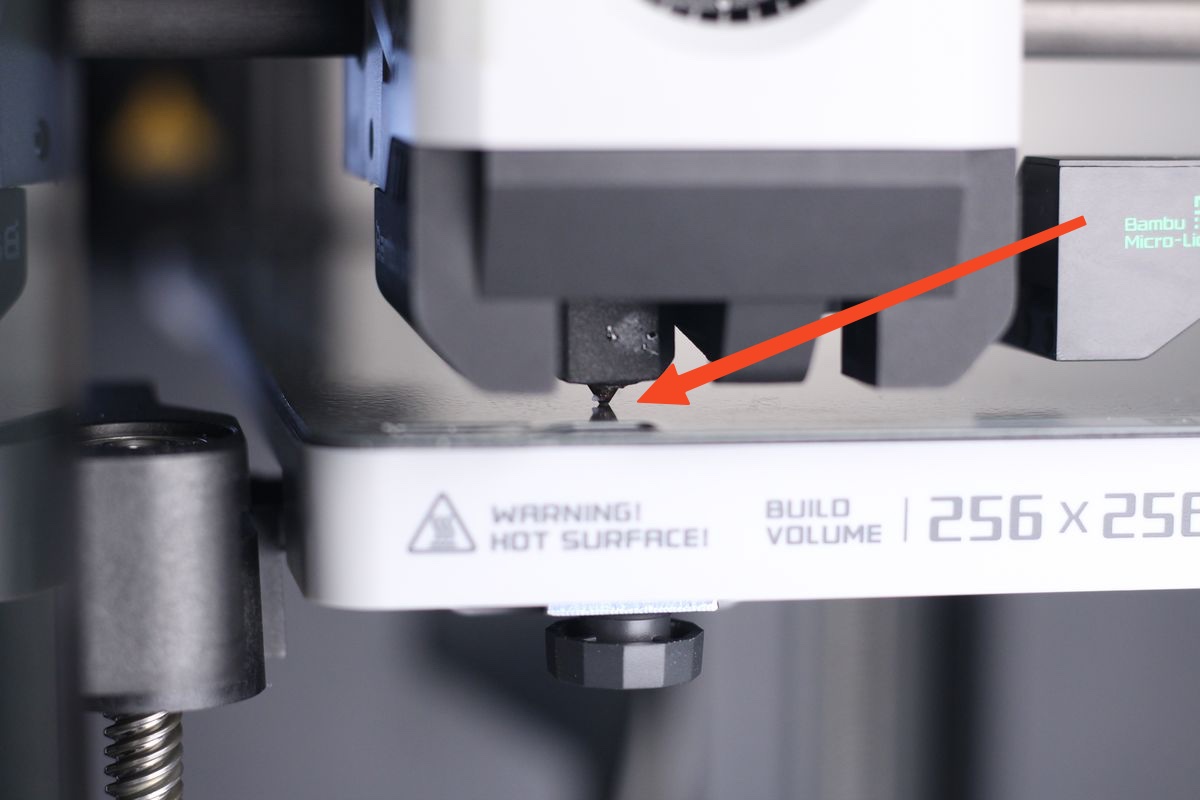

Once the bed is physically trammed, the printer’s Auto Bed Levelling (ABL) takes over before each print to measure minor variances. Bambu printers do not use a typical nozzle-mounted probe like BLTouch; instead, they have force sensors under the bed. The nozzle itself taps the bed at a grid of points, and the bed’s strain gauges detect when contact is made.

The X1 series adds its LiDAR scanner to double-check the bed surface, thus the “Dual ABL” system where “the LiDAR and analog force sensors crosscheck for an extra layer of redundancy”. The result is a detailed mesh of the bed that the printer uses to adjust Z height during the first layers, ensuring the filament is pressed evenly everywhere. The user doesn’t need to do anything except keep the bed clean (fingerprint oils can affect sensor readings and adhesion).

It’s generally recommended to allow ABL before every print (Bambu Studio enables it by default) for consistent results – the time penalty is small (~1 minute) and it can compensate for thermal expansions or any slight shifts. If you truly trust your bed and want faster startup, you can disable ABL in the slicer but proceed with caution. Most of the time, leave it on for peace of mind.

Nozzle Height (Z-offset)

Along with levelling, the printer needs to set the correct gap between the nozzle and bed. The X1 and others handle this automatically as well – typically as part of the levelling or a separate “Z calibration” routine. If the printer detects the nozzle is too low (perhaps due to a slightly worn nozzle tip or leftover filament on it), it will warn you (with messages like “nozzle height seems too low”, prompting calibration).

On the X1C, the LiDAR can actually scan the first layer lines to see if they’re squished properly and adjust live. On other models, the first-layer flow calibration feature can also dial this in (more on that later). If you ever need to adjust Z-offset manually (for example, to fine-tune first layer squish), you can do so via the printer’s menu or Bambu Studio’s first layer Live Adjustment slider. However, ideally, if bed levelling and nozzle calibration are working, you shouldn’t have to manually baby-step the Z.

Tip: Always start prints with a clean bed and clean nozzle. A bit of hardened filament stuck to the nozzle can throw off the force sensor on the first tap, and a greasy bed can mess up adhesion and the levelling measurement. Bambu’s documentation specifically notes to wash the plate or use a glue stick if needed, because if the calibration line doesn’t stick, the sensor (especially LiDAR) can’t read it properly.

Flow Dynamics Calibration (Pressure Advance – “LiDAR Flow”)

One of Bambu Lab’s headline features is Flow Dynamics Calibration, often informally called pressure advance calibration. This is the routine where the printer adjusts for the lag in extrusion during accelerations and decelerations. In simple terms, when printing at high speed, the filament pressure in the nozzle lags behind sudden speed changes. As you speed up, filament flow initially can’t keep up (causing thin lines or gaps), and as you slow down, excess pressure can ooze out (causing blobs on corners).

Flow Dynamics compensation pre-emptively tweaks the flow to counteract these effects. Think of it like “stepping on the gas a moment early and easing off the gas a moment early” so that the actual output of plastic remains consistent. Bambu printers calibrate this by determining a “Factor K” (the pressure advance value) for each filament.

How it works

On the X1 series, this calibration uses the Micro LiDAR and a special printed pattern. The printer will draw a series of lines on the build plate at varying speeds, then the LiDAR scanner measures those lines’ width to see how consistent the extrusion was. Based on that, it calculates the optimal K value.

On the A1 series and H2D (which don’t have LiDAR), the printer uses an eddy-current force sensor in the toolhead: it performs the calibration by extruding filament through the nozzle (usually at the purge/overflow chute to avoid messing the bed) and measuring the force needed as it accelerates and decelerates extrusion. Essentially, it’s feeling the pressure directly rather than scanning a printed line. Both methods yield a recommended Flow Dynamics value.

The P1 series, lacking both LiDAR and the new eddy sensor, does not support automatic flow dynamics calibration – P1 users can still do it manually (more on that below), but they don’t have a one-button auto routine.

When to run Flow Dynamics Calibration

You should perform a flow dynamics (pressure advance) calibration for each new filament type/brand, especially if you notice issues like blobs at corners or inconsistent extrusion when printing fast.

Bambu Studio can automate this process (Devices -> Calibrate -> Flow Dynamics -> Auto) for X1, A1, H2D. Common scenarios to recalibrate include switching to a different filament brand or material, or after changing to a fresh nozzle (since different nozzle geometry or wear can change the pressure dynamics). The calibration result is stored per filament profile: on X1/A1, it saves a Factor K associated with that filament in the AMS or Studio profile.

On next use of that filament, the printer can skip calibration and use the saved value – unless you have it set to always run. By default, Bambu printers do run a flow dynamics test at the start of each print (that quick “squiggle” or line it prints and scans) on X1, or the purge-force test on A1. This ensures optimal tuning every time, but it does consume a bit of time and filament.

Experienced users disable the per-print calibration after obtaining a good value, to save time. As noted by a community member, “the automatic test’s Factor K will always trump the manual profile if you run it… Only reason not to is if you are picky about control or don’t want to waste time/material every print.”

If you trust your saved calibration, you can uncheck “Flow Calibration” before slicing to skip it – just remember to recalibrate if something (filament, nozzle) changes or if print quality issues creep back.

Reliability: For the X1’s LiDAR method, there are a few cases where auto calibration might be unreliable. For example, transparent or very glossy filaments confuse the laser scanner, so the X1’s LiDAR may mis-read those lines. A textured PEI bed can also scatter the laser, though Bambu’s firmware tries to account for that – if using textured plate and having trouble, you might switch to a smooth plate for calibration.

The BambuWiki also notes damp filament can throw off results (damp filament extrudes differently) and extremely soft TPU filament often fails the calibration. In those scenarios, or if you have a 0.2mm micro-nozzle (which Bambu explicitly says tends to give inaccurate auto-calibration results), it’s best to do a manual calibration instead. Manual flow dynamics calibration prints a pattern (usually a set of lines or a tower) and requires you to visually pick the best one, then input the K value. OrcaSlicer, for instance, has a nice pressure advance tower that many P1/P1P users rely on. The Bambu Wiki suggests using the “pattern” mode over single-line mode if you do manual calibration on a textured plate, since a thicker pattern is less affected by the texture.

TL;DR

Pressure advance is like using a toothpaste tube: if you want an even line of toothpaste while moving the tube, you need to squeeze a bit extra when you start moving (to get flow going) and ease off before you stop (so you don’t get a blob at the end). The Flow Dynamics calibration teaches the printer exactly how much to “squeeze or ease” for a given filament at given accelerations. 🦾

Result: After calibration, you’ll have an optimal K (flow dynamics) value saved. This usually ranges from around 0.0xx to 0.2 depending on material. A higher K means more aggressive compensation. If you ever see issues like slight bulges at corners, you might need to recalibrate or fine-tune that value. Many advanced users actually run both auto and manual calibrations and then choose a balanced value.

One user described doing auto, then manual, and averaging results to get perfection – “auto gets good to great results, but manual tuning gets results to perfection… auto PA was slightly off on corners, I fine-tuned it”. That’s the level of tweaking you can do if you want ultra-clean corners on fast prints. But for most, the auto calibration suffices to significantly reduce ringing, blobs, and other artifacts from rapid speed changes.

Bambu Lab’s Micro LiDAR module (dual red laser) for the X1 series, which scans printed lines to calibrate flow dynamics and first-layer quality. This sensor gives the X1 an edge in fully automating pressure advance tuning (the so-called “LiDAR flow calibration”). Other models like the A1 and H2D use a force sensor instead of a laser to achieve similar automatic calibration.

Flow Rate Calibration (Extrusion Multiplier Tuning)

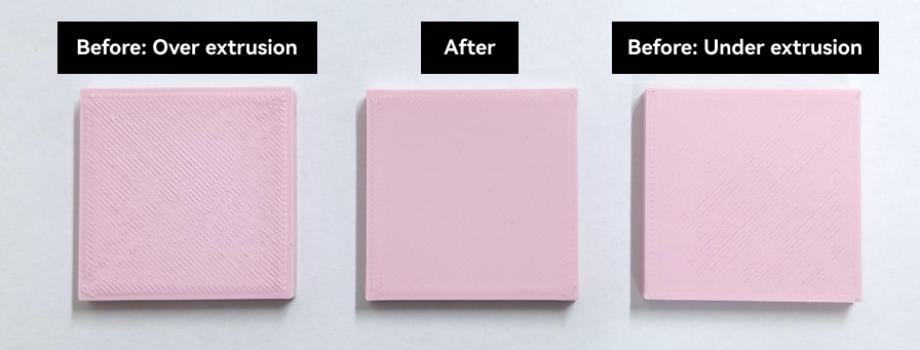

While flow dynamics deals with pressure during accelerations, Flow Rate Calibration deals with the overall extrusion volume to ensure your printer isn’t over- or under-extruding in steady-state. This is essentially tuning the extrusion multiplier or flow ratio for a filament. If you’ve ever seen prints with bulging walls or globbed top layers (over-extrusion) or conversely thin, delaminated layers (under-extrusion), flow rate calibration is the remedy. Bambu Lab printers come with well-tuned defaults (especially if using Bambu brand filament profiles), but when using third-party filaments, a flow rate tweak can sometimes dramatically improve surface quality.

In Bambu Studio, the Flow Rate Calibration routine prints a set of small square patches (each with a slightly different flow percentage) so you can choose which one has the smoothest, fully fused top surface. There is an Auto mode for X1 series only, which again uses the LiDAR: it prints patterns and the LiDAR measures them to directly compute the optimal flow ratio. This auto flow rate calibration with LiDAR is a newer feature (it’s in Studio 1.7+ as an experimental feature) and it comes with some caveats – Bambu labels it “for experienced users” because incorrect usage could clog a nozzle (for instance, if it pushes too much filament). It’s also limited by filament type (shiny, transparent, etc., are not supported for auto, similar to the flow dynamics case).

For A1 and P1 series, manual flow rate calibration is the way to go, and thankfully it’s straightforward.

Manual Flow Rate Calibration

The goal is to find the flow percentage where a solid filled layer is just right – not overfilled (causing ridges or ripples) and not underfilled (causing gaps between lines). Bambu’s method prints several 2-layer squares each with a different flow multiplier (say 90%, 95%, 100%, 105%, 110% as an example). Once printed, you examine the top of these squares and pick the one with the smoothest, most uniform surface. Over-extrusion shows up as raised lines or a textured, rough surface; under-extrusion shows as visible gaps or an inconsistent infill pattern.

The correct one will look smooth and feel flat to the touch. You then take that flow value and either set it in the filament’s profile or save the calibration result in Studio (if using the built-in calibration dialog). Bambu Studio’s calibration interface allows a coarse and fine calibration: coarse might test e.g. 80–120% in 5% increments to narrow the range, and fine might test ±5% around the best value in 1% increments.

The end result is a Flow Ratio (%) for that filament, which gets stored in a new filament profile or applied to the current one. For example, you might determine that “Brand X PLA red” flows best at 1.05 (105%), so you make a profile for it with flow = 105%. Next time you use that filament, those settings are ready to go.

When to do it

If you notice signs of over or under extrusion (blobs, zits, or conversely weak infill and thin walls) after having done the dynamic flow calibration, then a flow rate calibration is warranted. It’s wise to do a flow rate test for each new filament brand, especially if you’re chasing top surface perfection.

Even with Bambu’s own filaments, occasionally a batch or color might benefit from a tiny adjustment (though generally they are tuned fairly well at default flow=1.0). As a bonus, for exotic filaments like LW-PLA (foaming lightweight PLA), calibrating flow rate is crucial – these materials expand when printing and finding the right flow multiplier can be the difference between a successful lightweight print and a blobby mess.

TL;DR

Flow rate is like how hard you squeeze the toothpaste tube overall. Too much paste (over-extrusion) and you get a messy blob; too little and there are gaps in the line. We want the Goldilocks amount for a nice even line.

In practice, many Bambu users find the default profiles get them “close enough,” but if you want those glassy-smooth top layers, spend a few minutes with a flow rate calibration print. It’s one of the easier calibrations to judge visually. As the Bambu wiki shows, a correctly tuned flow has aligned layer lines that form a smooth surface. In contrast, over-extrusion will leave a rough feel or visible ridges, and under-extrusion leaves unfilled gaps. Adjusting by even ±5% can significantly change the top layer quality, so it’s worth dialing it in.

Example of a flow rate calibration pattern (multiple squares), each printed with a different flow ratio from 0.93 up to 1.07. By comparing the surfaces, you identify which flow rate produces the smoothest top layer and use that value for your filament. In this example, the squares are labeled with their flow multiplier ranges.

Advanced tip: The X1’s new Auto Flow Rate (LiDAR) calibration (in Bambu Studio 1.7) attempts to do what your eyes do, but via lasers. It prints several lines at different flow rates and measures actual extruded volume to suggest an optimal flow ratio. It’s a cutting-edge feature but be cautious – it’s still being refined and may not support all filaments. If you use it, be sure to follow all prep instructions (correct filament preset, bed temp, etc. to avoid miscalculation). For most users, manual calibration or using OrcaSlicer’s calibration presets (which many find very convenient) is sufficient and reliable.

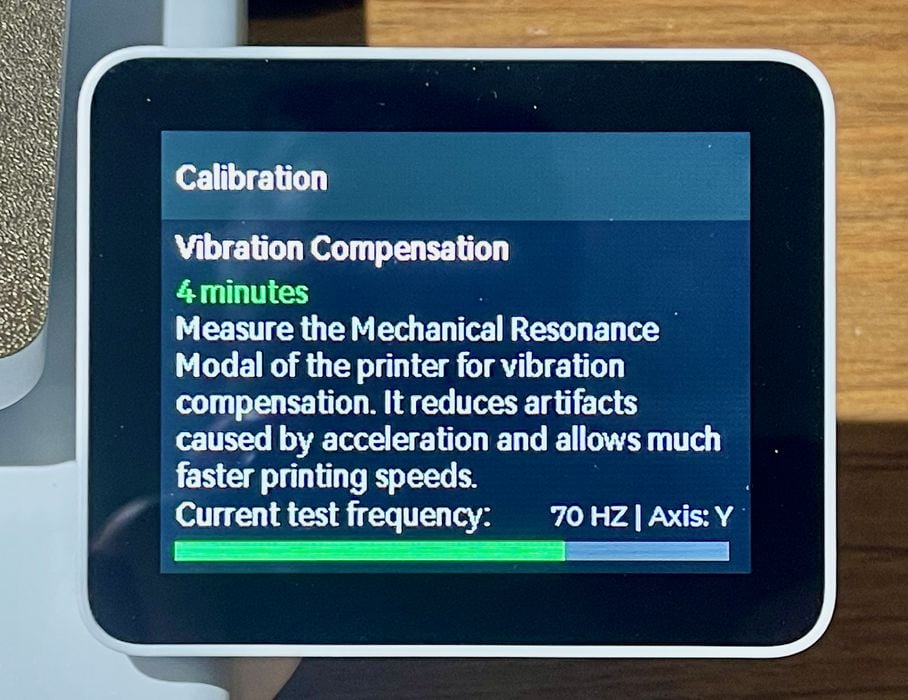

Vibration Compensation Calibration (Resonance Tuning / “Input Shaping”)

Bambu Lab printers are built for speed, and moving fast can introduce vibrations (ringing or ghosting on printed parts). Vibration Compensation calibration is essentially the printer tuning itself to cancel out resonances. This is analogous to the “input shaping” calibration done on Klipper-based printers using an accelerometer. Bambu has this feature integrated and automated.

During vibration calibration, the printer will likely move the print head in a certain pattern and use either an accelerometer or motor feedback to detect oscillation frequencies. The process takes just a couple of minutes and results in the machine setting parameters to mitigate those vibrations. In practice, after running vibration compensation, you’ll notice sharper details and less echoing of features on your prints, even at high speeds.

On the X1/P1, you can initiate this by going to Calibration -> “Vibration Compensation” on the screen and hitting Start.

The A1 series also includes this (often combined in the initial setup wizard). No filament is needed, as it’s just moving axes. What exactly is happening? The printer is finding its resonant frequencies – every mechanical system has certain frequencies at which it shakes more (like how a car might rattle at certain engine RPMs). The calibration identifies those and adjusts the motion planning to avoid exciting them. Bambu’s wiki explains: “During acceleration and deceleration, the printer excites resonant modes, causing oscillations. The resonance detection process finds the frequency and enables vibration compensation adjustments”. In plain terms, it figures out how to “pre-wiggle” or “deaden” motions to stop ringing.

When to run it

It’s good to run once when the printer is new or if you move the printer to a new location (especially if you change something like adding rubber feet or changing the surface it sits on, which could alter vibration behaviour). Also, if you tighten belts or make other hardware changes, re-run it. Otherwise, it generally doesn’t need frequent re-calibration.

The P1 series in particular benefits from this, as those models encourage users to push speeds where ringing would show without compensation. The X1 series and others come pre-tuned but running it can only help if anything shifted in transport.

This calibration is usually quick (a few minutes). You might hear the printer make some hums or quick movements – that’s normal. After it’s done, the printer’s firmware activates the compensation automatically during prints. There isn’t a “user value” you see or set; it’s behind the scenes. But the effect should be visible on test prints: try printing a cube with text or a pattern on it before and after calibration, and you should see crisper edges post-calibration.

Tip: ensure the printer is on a stable surface when running this. If it’s wobbling on a rickety table during calibration, you might not get an optimal result. Also, do not physically touch the printer while it calibrates.

In summary, vibration calibration = better print quality at high speed. It’s great that Bambu automates this – just another piece of the puzzle to keep prints looking clean. As Bambu puts it, this “significantly improve[s] printing speed” because the printer can push harder without quality loss.

Motor Noise Cancellation Calibration

This calibration is less about print quality and more about the audible noise and smoothness of the printer’s motors. Bambu printers have a feature to actively cancel stepper motor resonances by applying a counter-vibration via the motors themselves. It’s a bit like noise-cancelling headphones but for stepper buzz. The calibration routine will drive the motors in certain ways to measure their “singing” and then set parameters to minimize that sound.

For the user, running Motor Noise Cancellation is usually done at initial setup (the A1 Mini’s startup wizard, for example, has checkboxes for Vibration and Motor Noise calibration right away). You can also trigger it anytime from the Calibration menu. It takes a few minutes and you might hear the printer making various tones as it tests the motors.

Under the hood, the printer is finding unwanted vibrations in the motors across their operating range and calculating how to counteract them in real time. Stepper motors can produce a high-pitch whining or buzzing due to microstepping and resonances. Bambu’s firmware, after calibration, will send slight phase-shifted signals to nullify those vibes. The result is a quieter printer and possibly slightly smoother motion. It doesn’t directly affect print geometry, but a quieter, smoother motor could indirectly reduce very fine micro-vibrations that could show up on surfaces (though vibration compensation is the bigger factor for print quality).

When to run it

Typically once when the printer is new or if you change something like the stepper drivers (which most users won’t). It’s largely a “set and forget” calibration. If you notice your printer has gotten louder over time or after some maintenance, re-running it might help regain some hush. It’s worth noting that some noises (fans, bearing noise, etc.) won’t be fixed by this – it’s targeting the motor noise specifically.

One interesting aspect – by reducing motor noise, the printer may be more comfortable to operate at night or in a shared space. Some users reported that running this made their P1P noticeably quieter in certain movements (though the fans on high speeds are still the dominant noise in many cases). Every bit helps if you’re seeking a quieter 3D printing experience.

Note: Make sure the printer is on a normal surface (not decoupled by heavy dampers) when running this, as it likely uses the frame as a reference for the motor’s vibration output. Other than that, it’s a straightforward calibration.

Dual Nozzle Calibration (H2D Specific)

With the H2D printer, Bambu Lab introduced dual independent nozzles (IDEX or 2-nozzle system). Calibration here gets an extra layer of complexity: you must ensure the two nozzles are aligned in Z (one nozzle not higher/lower than the other) and in X/Y (so they print in the exact same spot when doing multi-material or support). Bambu has fully automated this process on the H2D, using both an eddy current sensor and an AI camera-based method for high precision.

Z-Offset Calibration (Nozzle Height Difference)

Ideally, the two nozzles are set 5 mm apart in height (one parks 5 mm above when not in use). But manufacturing tolerances or mounting can introduce small errors. The H2D does a routine where each nozzle in turn touches the bed (utilizing the bed’s force sensors) to measure exactly how far apart they are. It then knows, for example, nozzle B is 5.05 mm below nozzle A instead of 5 mm, and compensates by adjusting Z when swapping. This is done automatically when you run Nozzle Offset Calibration -> Z-direction on the machine. It’s quick – effectively just a double homing of each nozzle to Z=0.

X/Y Offset Calibration (Baseline)

The H2D has a nozzle offset calibration sensor located at the rear right of the bed – described as “a protruding small black piece on the right behind the heatbed”. This is likely an eddy-current or magnetic sensor target. The calibration routine will move both nozzles around that sensor and detect their positions. Essentially, each nozzle finds the center of that sensor (by where the signal is strongest) and the printer calculates the difference in coordinates between nozzle 1 and nozzle 2. That gives the coarse X and Y offset. Bambu provides two modes before printing: a Complete calibration (~70s) which presumably does a thorough job with that sensor, and a Quick calibration (~20s) which might use a previously known offset unless it seems off. These can run automatically before a print if you have the option toggled (you can set “Nozzle Offset Calibration” to Off, On, or Auto in the settings: Off means use saved values, Auto means quick check each time). The key point: the H2D can calibrate its nozzle alignment on the fly, so you don’t have to print manual alignment patterns as was common with older dual-extruder machines. Bambu advertises this as “fully automatic X/Y offset calibration using a proprietary eddy sensor”, so you can “say goodbye to manual X/Y calibration”.

High-Precision (AI Visual) Calibration

For the ultimate accuracy, the H2D also offers a high-precision calibration routine. In this mode, the printer will actually print a test pattern with both nozzles – typically a set of cross lines in two colors – and then use the built-in camera to visually analyze the offset. The process involves printing, say, one nozzle draws an X and the other nozzle draws a + over it in a different filament, and the camera checks alignment. The firmware then computes the exact X/Y offset with (theoretically) higher accuracy than the sensor method. According to the wiki, this can achieve ~15–20 µm accuracy in positioning. The caveat is that it’s more involved – you need two contrasting color filaments loaded (one in each extruder) for the camera to distinguish the lines. And it takes longer. It’s something you might run only occasionally, or if you suspect the simpler calibration isn’t perfect. After running it, those refined offsets can be used (the wiki notes you have to turn off the regular offset calibration if you want to use the high-precision result exclusively).

Putting it together

If you own an H2D, to calibrate, you would typically: run the regular Nozzle Offset Calibration (which does Z and XY using sensor) when you set up the machine, and then enable the pre-print Auto or Quick calibration so it checks each time the printer starts a dual-nozzle job (this handles any slight drift or if you swapped a hotend, etc.). If you notice any misalignment in dual-color prints or similar, run the High-Precision calibration with a dark and light filament as instructed. That should dial it in precisely. The system is designed so that even if you, say, replace a nozzle or a hotend, the printer can re-calibrate itself easily without manual fiddling. Just be aware of the potential failure causes: the wiki mentions things like if the sensor is damaged or third-party nozzles that aren’t magnetically detectable can cause calibration to fail. Use official parts for best results or at least know that fancy hardened nozzles might not trigger the sensor (so you’d then rely on the camera method in that case, perhaps).

Dual-nozzle calibration might sound complex, but Bambu has largely made it automatic. It’s a huge convenience – older dual-extruder printers often required printing a calibration grid and manually measuring offsets. Here, you tap a button, and it aligns itself. If you run these routines, your two colours or materials should print right on top of each other with no ghosting or shifts, and your support nozzle will line up perfectly under the model.

Calibration Tips, Techniques and Best Practices

Now that we’ve covered each calibration mode, let’s summarize some best practices and tips gleaned from the community to ensure you get the most out of your Bambu printer’s calibration features:

- Do the Basics First: Always start with mechanical checks – a clean nozzle and bed, properly tightened screws, belts tensioned, etc. Calibration routines assume the hardware is in decent shape. For example, bed levelling won’t help if a corner of your bed is literally loose. And a blob of filament on the nozzle can throw off sensor readings. Spend a moment to wipe the nozzle and clean the plate before hitting “Calibrate”.

- Manual Tramming if Needed: If you suspect the factory levelling is off (common hint: one side of first layer always too high/low), perform the manual bed levelling (tramming) procedure. It’s a one-time or very occasional thing, but it lays the foundation for all other calibrations by giving the auto system a level playing field (pun intended). A well-trammed bed + mesh levelling = perfect first layers.

- Use the Right Plate for Calibration: The smooth PEI plate is generally recommended for calibration prints (flow and PA) because it presents a uniform surface for the LiDAR or visual inspection. Textured plates can be used (and many users do) – the system compensates to an extent – but if you run into issues with calibration accuracy, try switching to smooth for the calibration process. Similarly, if using high-speed calibration in Orca, some recommend using smooth plate for consistency.

- Filament Matters: Calibrate with the filament you plan to use for the print, and for critical calibrations like flow dynamics and flow rate, re-calibrate if you change filament brand or type. Even different colors of the same brand can have different optimal values (especially with pressure advance and flow). Profiles are cheap – make one per filament spool if needed. Bambu Studio/AMS will save PA (K) and Flow values per filament name, so utilize that.

- Dry Your Filament: If a filament is moisture sensitive (like Nylon, PETG to a lesser degree, TPU, etc.) and it’s been out, consider drying it before calibration. As noted, damp filament can skew calibration – it might extrude inconsistently during the test, giving you a wrong recommendation. A calibration done on soggy filament will not hold true once the filament is dry (or vice versa).

- Calibrate in Logical Order: Generally, do vibration and noise calibration first (they are independent of filament). Then do flow dynamics (PA) calibration for your filament, then flow rate calibration. Temperature tuning (if you venture into that) would actually come before these, because your print temperature affects viscosity and flow. Some advanced users will do temp towers and set an optimal temp before doing flow calibrations. But if you’re using known good temps, you can skip straight to flow. The reason to do PA before flow rate is that pressure advance can slightly affect how extrusion lines form, and you want that dialed in prior to fine-tuning the flow multiplier.

- Save and Label Profiles: When you get good calibration values, save them into a filament profile with clear naming (e.g., “eSun PLA+ Blue – 0.4 nozzle”). Bambu Studio allows multiple profiles even for same filament type. That way you don’t have to recalibrate next time; just load that profile. Also note nozzle size in the profile name if you ever swap nozzles – a 0.6 mm nozzle will have different flow behavior than 0.4 mm.

- Don’t be Afraid to Turn Off Auto Calibration (when appropriate): This sounds counterintuitive, but once you have things dialed in for a particular filament, you might disable the auto flow calibration at print start to save time/material. Many users do this: they run the dynamic flow and flow rate calibrations once, then in Bambu Studio uncheck “Flow Calibration” for that filament going forward. The printer will then skip that little routine each time (no more “two lines dance” before printing), shaving a minute or two off each job and avoiding that bit of filament waste. However, if you change to a different filament or even a different color of the same type, remember to either re-enable it or load a profile with the appropriate saved values. It’s all about confidence in your saved calibration. If you notice the first layer or corners aren’t as perfect after turning it off, maybe re-run it or leave it on. Bed leveling, on the other hand, is so quick and beneficial that most leave it on every time – you can disable it, but unless you’re doing back-to-back identical prints, it’s usually not worth the risk.

- Utilize OrcaSlicer for Advanced Calibrations: OrcaSlicer (a community fork of Bambu Studio) has a fantastic calibration toolset with preset tests for flow, PA, max volumetric speed, etc., that are a couple clicks to run. Many advanced Bambu users will use Orca just for calibration, then plug those numbers into Bambu Studio. Orca can do things like automatically modify the G-code to do a stepped calibration object. It’s essentially streamlining what you could do manually. This is not necessary, but it’s a good tip: “some people use OrcaSlicer to calibrate a filament then put the profile in Bambu Studio”. The results are the same, it’s just sometimes more convenient. Bambu is likely to add more of these conveniences into their official slicer over time (they already started with built-in flow and PA calibration routines).

- Maximizing Speed – Calibrate Maximum Flow Rate: An optional advanced calibration is finding your filament’s maximum volumetric speed (MVS) – basically how many mm³/s of filament can be pushed before quality degrades. OrcaSlicer includes a Max Flowrate test that prints a curved single-wall object with increasing speed to see where extrusion starts to falter. By calibrating this, you can set your slicer to not exceed that flow in slicer settings (Bambu Studio’s filament settings have Max volumetric flow rate parameter). Bambu’s default profiles are conservative in these values. If you find your filament can handle more, you can increase it and thus enable faster print speeds in Sport or Ludicrous mode without worrying about under-extrusion. As the forum guide said, “This widens the window of speeds available… it may let you print in Sport or Ludicrous when before it would fail!”. This is a bit beyond basic calibration, but for speed demons it’s worth exploring.

- AMS (Multi-Material) Considerations: If you use the AMS with multiple filaments, remember that calibrations are stored per filament name. The AMS can only tag filaments by certain presets or generic names (though you can rename). Make sure you either calibrate each spool (if they are different brands) or at least switch the AMS slot to a profile with the right calibration before printing. There was some confusion in community about whether the AMS would remember a calibration if you put, say, “Generic PLA” in two slots with different actual brands. It’s safest to create distinct filament profiles (even if both are PLA) so you can assign calibrations properly.

- When Things Fail: If a calibration ever fails (e.g., you get a “Flow calibration failed” message or a nozzle offset calibration error), consult the specific error in Bambu’s wiki. Often it’s due to the reasons discussed: clear any strings or debris, ensure the bed had good adhesion for the pattern, check that the sensors are clean (e.g., no obstructions on the LiDAR or camera lens for X1, no magnetic interference for H2D’s sensor). Bambu printers have HMS (Health Monitoring System) codes that correspond to calibration issues, and the wiki has entries for those as well.

- Firmware Updates: Occasionally Bambu improves calibration algorithms in firmware updates. For example, they were refining the LiDAR scanning logic and adding the high-precision nozzle calibration in updates. Keeping firmware updated ensures you have the latest fixes (one example from the wiki: an early firmware had a bug in nozzle offset sensor reading that was fixed in v01.01.02.08). So, update firmware if you’re experiencing odd calibration behavior that others don’t seem to have.

By following these practices, you’ll maintain a well-calibrated machine that produces stellar results. The combination of auto bed leveling, LiDAR/eddy-assisted flow calibrations, and smart vibration cancellation is what allows Bambu Lab printers to print fast and keep quality high. Take the time to let these systems do their job – run the calibrations that need running – and you’ll be rewarded with hassle-free printing.

As a final thought: calibration in 3D printing can feel like an art, but Bambu Lab has turned much of it into science with push-button ease. Happy printing and enjoy those perfectly tuned first layers and beautifully smooth prints!